Ergonomics

Yamazaki Mazak has always focused on not only improved machine performance but also machine ergonomics in order to realise unsurpassed ease of operation.

Excellent Accessibility

(Shown VARIAXIS i series)

Convenient workpiece loading / unloading

Unsurpassed access to the machine table for convenient workpiece loading / unloading. An overhead crane can be easily used for the loading / unloading of heavy workpieces and fixtures thanks to the automatic retractable top cover.

(shown VARIAXIS i-500 top cover opens separately)

Convenient tool magazine access

The tool magazine is located at the front of the machine eliminating the time required for the operator to go back and forth to the rear of the machine.

(Shown INTEGREX i series)

Large window

The large front door window allows workpiece machining to be easily monitored by the operator.

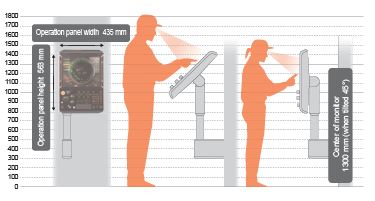

Adjustable CNC touch panel

The operation touch panel can be tilted to the optimum position for any operator's height to ensure ease of operation.

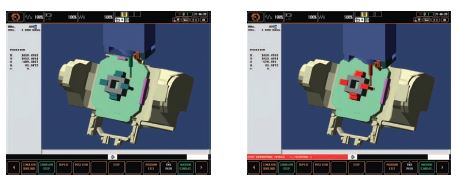

SAFETY SHIELD

When an operator manually moves the machine axes for setup, tool measurement or changing inserts, the CNC shows a synchronized 3D model on the display for checking machine interference. If any machine interference occurs, the machine motion automatically stops. This function is also effective during automatic operation.

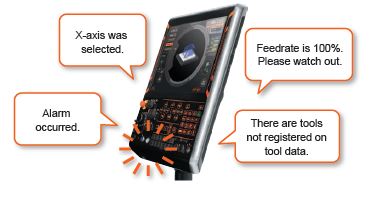

VOICE ADVISER

Verbal support for machine setup and safe conditions confirmation